Digital Twins In Automotive Manufacturing

Digital Twins in Automotive Manufacturing represent a transformative approach where virtual replicas of physical assets are utilized to enhance operational efficiencies and innovation. Within the automotive sector, this concept aligns closely with the integration of artificial intelligence, enabling stakeholders to simulate, predict, and optimize manufacturing processes. As digital twins become increasingly relevant, they empower companies to streamline production, improve quality control, and foster collaboration among teams, thereby redefining traditional practices.

The significance of the automotive ecosystem in leveraging digital twins is profound, as AI-driven methodologies reshape competitive dynamics and accelerate innovation cycles. These technologies enhance decision-making capabilities and operational efficiency, laying the groundwork for long-term strategic initiatives. However, while the potential for growth is substantial, challenges such as integration complexity and evolving stakeholder expectations pose hurdles that must be navigated to fully realize the benefits of this digital transformation.

Accelerate AI Integration for Digital Twins in Automotive Manufacturing

Automotive manufacturers should strategically invest in AI-driven Digital Twin technologies and form partnerships with leading tech firms to enhance data analytics capabilities. By implementing these AI strategies, companies can expect significant operational efficiencies, reduced costs, and a stronger competitive advantage in the evolving market landscape.

How Digital Twins Are Revolutionizing Automotive Manufacturing?

The Disruption Spectrum

Five Domains of AI Disruption in Automotive

Automate Production Flows

Optimize Supply Chains

Enhance Generative Design

Simulate Testing Environments

Boost Sustainability Efforts

Compliance Case Studies

| Opportunities | Threats |

|---|---|

| Enhance market differentiation through tailored automotive digital twin solutions. | Risk of workforce displacement due to increased AI automation. |

| Strengthen supply chain resilience with AI-driven predictive analytics tools. | Increased technology dependency may lead to operational vulnerabilities. |

| Achieve automation breakthroughs via real-time digital twin simulations. | Potential compliance bottlenecks with evolving regulatory frameworks. |

Embrace the transformative power of Digital Twins in Automotive Manufacturing. Gain a competitive edge and elevate your operations today—don’t miss out on the future of innovation.

Risk Senarios & Mitigation

Ignoring Data Privacy Regulations

Data breaches lead to fines; enforce robust data policies.

Overlooking System Security Vulnerabilities

Cyberattacks cause operational disruption; conduct regular security audits.

Failing to Address Algorithmic Bias

Unfair outcomes harm reputation; implement bias detection tools.

Underestimating System Integration Challenges

Operational failures arise; invest in rigorous testing protocols.

Assess how well your AI initiatives align with your business goals

Glossary

Work with Atomic Loops to architect your AI implementation roadmap — from PoC to enterprise scale.

Contact NowFrequently Asked Questions

- Digital Twins in Automotive Manufacturing creates virtual replicas of physical assets for real-time insights.

- This technology optimizes production processes, enhancing operational efficiency and reducing costs.

- It enables predictive maintenance, minimizing downtime and improving asset longevity.

- Companies gain competitive advantages by accelerating innovation and product development cycles.

- Overall, it enhances decision-making through data-driven insights and analytics.

- Begin by assessing your current manufacturing processes and identifying key areas for improvement.

- Engage stakeholders to define objectives and align on the vision for implementation.

- Develop a roadmap outlining timelines and resource allocation, focusing on critical success factors.

- Select suitable technologies and platforms that integrate seamlessly with existing systems.

- Pilot projects can validate concepts before scaling the Digital Twin initiatives across the organization.

- Data integration and quality issues often hinder effective implementation of Digital Twins.

- Resistance to change among employees can complicate the adoption of new technologies.

- Ensuring cybersecurity measures is crucial to protect sensitive manufacturing data.

- Costs associated with technology and training can pose financial challenges for organizations.

- Best practices include engaging stakeholders early and continuous monitoring of project progress.

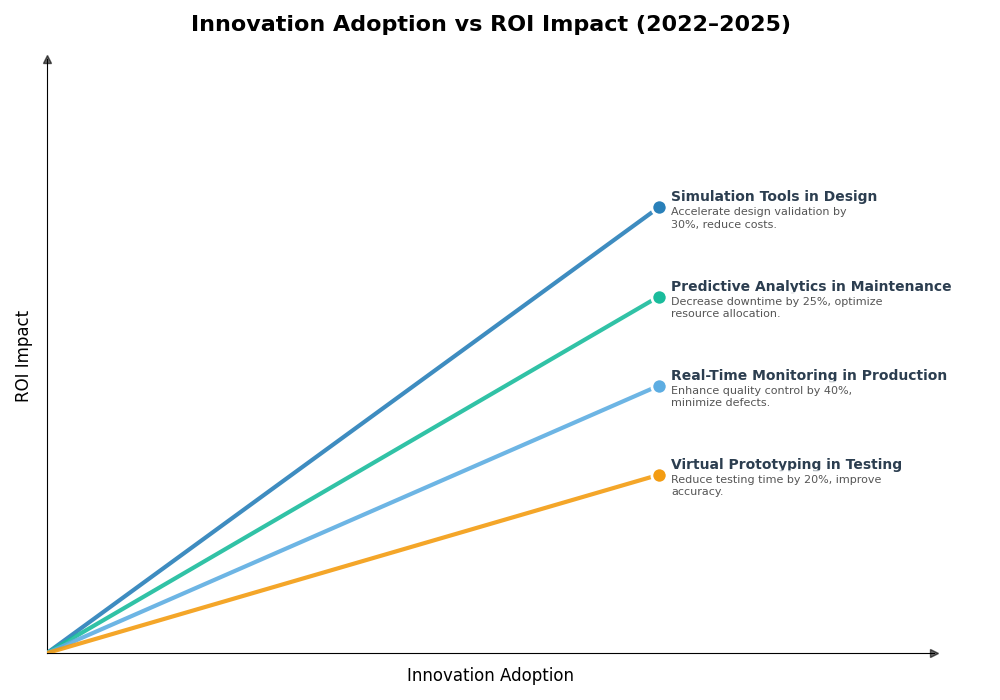

- AI-driven Digital Twins enhance operational efficiency through predictive analytics and automation.

- They enable real-time monitoring, allowing for immediate responses to production anomalies.

- The technology fosters innovation by simulating scenarios and optimizing design processes.

- Companies can achieve significant cost savings by minimizing waste and resource inefficiencies.

- Ultimately, adopting AI-driven Digital Twins strengthens competitive positioning in the market.

- ROI can manifest as reduced operational costs and increased throughput over time.

- Companies often see improved product quality, leading to higher customer satisfaction rates.

- Predictive maintenance capabilities minimize downtime, translating to significant cost savings.

- Enhanced agility in manufacturing processes allows for faster response to market demands.

- Organizations should establish clear metrics to measure success and adjust strategies accordingly.

- The optimal time to implement Digital Twins is during major technological upgrades or system overhauls.

- Organizations should consider implementation when experiencing inefficiencies or rising operational costs.

- Market demands for rapid innovation can also prompt timely adoption of Digital Twin technology.

- Engaging in pilot programs when ready can help gauge effectiveness before full-scale deployment.

- Continuous assessment of industry trends can indicate readiness for Digital Twin integration.

- Compliance with industry standards is crucial when implementing Digital Twin technologies.

- Data protection regulations must be considered, especially concerning sensitive manufacturing information.

- Organizations should evaluate how digital twins affect existing compliance frameworks and liabilities.

- Engaging legal experts early in the process can mitigate risks associated with regulatory non-compliance.

- Continuous monitoring of regulatory changes is essential to ensure ongoing compliance and adaptation.

- Benchmarking against leading automotive manufacturers can provide insights into best practices.

- Assessing the maturity of digital technologies within your organization can guide your strategy.

- Monitoring industry trends helps identify successful Digital Twin applications and innovations.

- Engaging with industry associations can provide access to relevant benchmarks and case studies.

- Regular evaluations against these benchmarks can keep your organization competitive and focused on growth.